Clutches and Brakes, Thomson

Danaher Motion/Deltran PT

Thomson has a long history of manufacturing quality clutches and brakes. Their roots are firmly planted in brand names such as Deltran, API (American Precision Industries), and Warner PSI bringing over 100 years of combined manufacturing experience. Deltran joined Danaher Motion in March 2000, followed in July 2000 by the acquisition of Warner PSI. The Genuine Wrap Spring and electromagnetic friction products were later combined under the Deltran name within the Thomson family.

Thomson's modern Amherst, NY facility is ISO 9001:2000 and AS9100-B certified for its Design, Manufacturing and Assembly of Motion Control Devices. Their brake and clutch manufacturing experience, technological knowhow and commitment to produce a quality product, delivered on time, every time.

Got Motion offers solutions with Thomson's Electromechanical Clutches (CS) and the SB series of brakes.

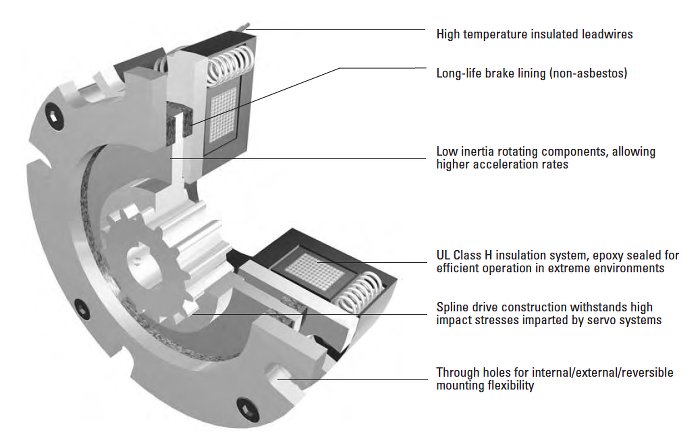

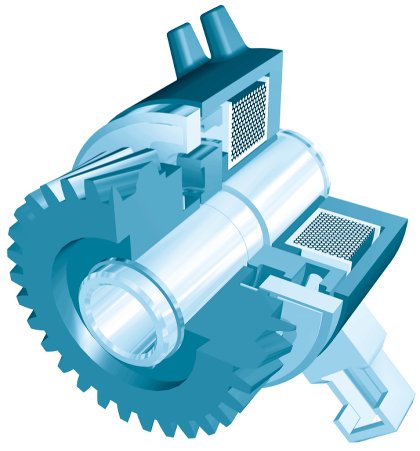

Electromechanical Clutches (CS)

Electromagnetic clutches provide an efficient, electrically switchable link between a motor and a load. Clutches are used to couple two parallel shafts by the use of pulleys, gears or sheaves. While the field (electromagnet) assembly is prevented from rotating by an anti-rotation tab or flange, the rotor and armature assembly are mounted on a single shaft, with the rotor secured to the shaft. The armature is bearing mounted and free to rotate. When the coil is energized, the armature engages the friction surface of the rotor, thus driving the load. Electromagnetic clutch couplings provide this same efficient, electrically switchable link between a motor and a load for in-line shafts. While the field (electromagnet) assembly is prevented from rotating by an anti-rotation tab or flange, the rotor and armature assembly are securely mounted on opposing in-line shafts. When the coil is energized, the armature engages the friction surface of the rotor, coupling the two in-line shafts, thus driving the load.

Brochure ( PDF )

Features:

- Torque: 2.5 to 125 lb-in

(0.28 to 14.12 Nm) - Diameters: 1.25 to 3.27 in

(31.8 to 83.1 mm) - Efficient means of cycling load

- Fast response, repeatable

- performance

- Static or dynamic engagement

- Simple installation

- Economic cost

- Energy efficient

Typical Applications:

- Document handling

- Copiers

- Printers

- Collators

- Sorters

- Finishers

- ATM machines

- Currency counters

- Vending machines

- Postal handling equipment

- Ticket & receipt dispensing

- Packaging

- Material handling

- Office automation

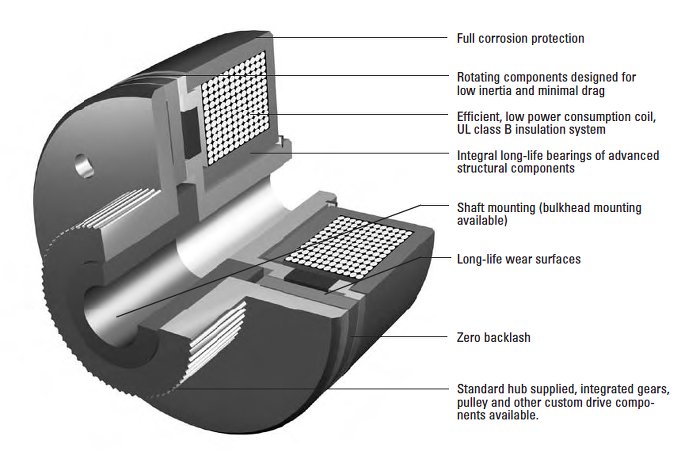

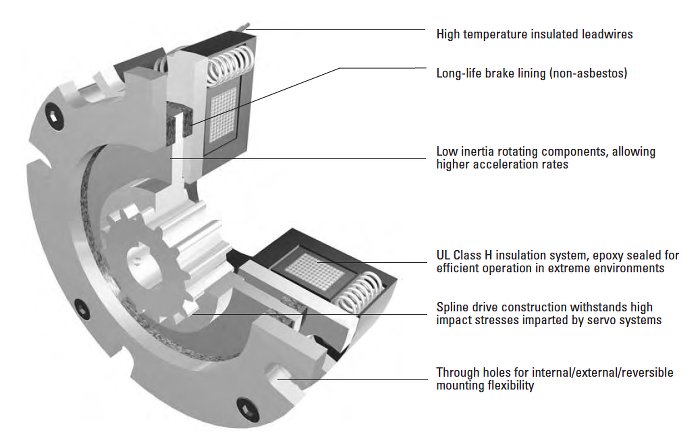

SB Series Power-off Brakes

Spring-set electromagnetic power-off brakes provide a safe, efficient means of stopping and/or holding a load in the absence of power. While the field (electromagnet) assembly is fixed and prevented from rotating, the rotor assembly is secured to the shaft. In the absence of power, the fixed and rotating components are engaged, thus stopping and/or holding the load. When the coil is energized, rotating components are disengaged thus allowing the shaft to freely rotate.

Brochure ( PDF )

Features:

- Torque: 2.5 to 125 lb-in

(0.28 to 14.12 Nm) - Diameters: 1.25 to 3.27 in

(31.8 to 83.1 mm) - Efficient means of cycling load

- Fast response, repeatable

- performance

- Static or dynamic engagement

- Simple installation

- Economic cost

- Energy efficient

Typical Applications:

- Typical Applications

- Robotics

- Medical equipment

- Actuators

- Motor brakes

- Postal handling equipment

- Packaging

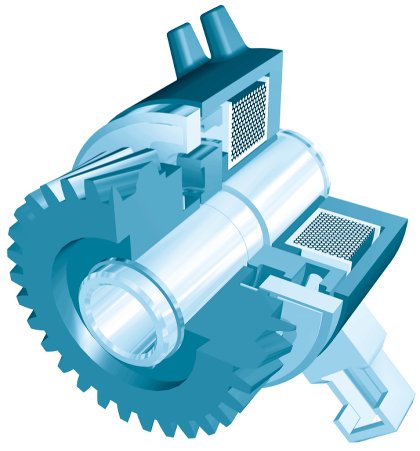

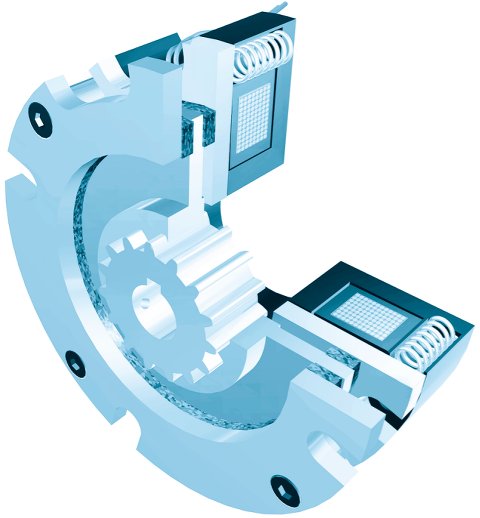

Electromagnetic clutches provide an efficient, electrically switchable link between a motor and a load. Clutches are used to couple two parallel shafts by the use of pulleys, gears or sheaves. While the field (electromagnet) assembly is prevented from rotating by an anti-rotation tab or flange, the rotor and armature assembly are mounted on a single shaft, with the rotor secured to the shaft. The armature is bearing mounted and free to rotate. When the coil is energized, the armature engages the friction surface of the rotor, thus driving the load. Electromagnetic clutch couplings provide this same efficient, electrically switchable link between a motor and a load for in-line shafts. While the field (electromagnet) assembly is prevented from rotating by an anti-rotation tab or flange, the rotor and armature assembly are securely mounted on opposing in-line shafts. When the coil is energized, the armature engages the friction surface of the rotor, coupling the two in-line shafts, thus driving the load.

Brochure ( PDF )

Features:

- Torque: 2.5 to 125 lb-in

(0.28 to 14.12 Nm) - Diameters: 1.25 to 3.27 in

(31.8 to 83.1 mm) - Efficient means of cycling load

- Fast response, repeatable

- performance

- Static or dynamic engagement

- Simple installation

- Economic cost

- Energy efficient

Typical Applications:

- Document handling

- Copiers

- Printers

- Collators

- Sorters

- Finishers

- ATM machines

- Currency counters

- Vending machines

- Postal handling equipment

- Ticket & receipt dispensing

- Packaging

- Material handling

- Office automation

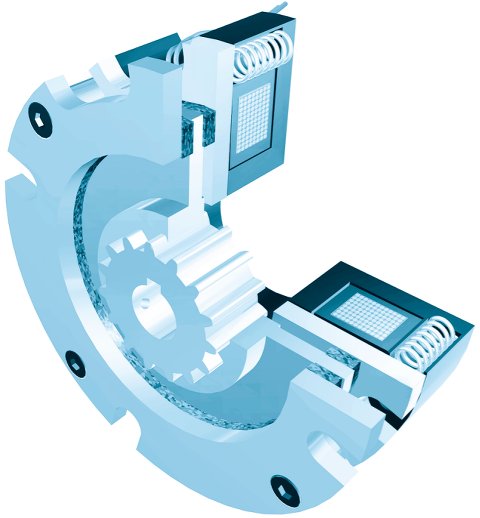

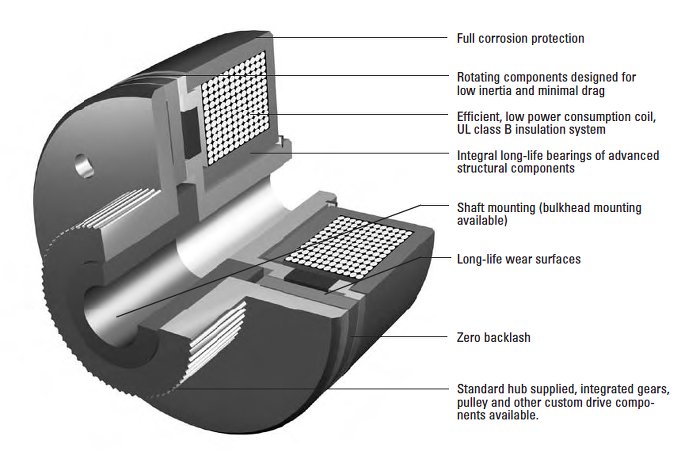

Spring-set electromagnetic power-off brakes provide a safe, efficient means of stopping and/or holding a load in the absence of power. While the field (electromagnet) assembly is fixed and prevented from rotating, the rotor assembly is secured to the shaft. In the absence of power, the fixed and rotating components are engaged, thus stopping and/or holding the load. When the coil is energized, rotating components are disengaged thus allowing the shaft to freely rotate.

Brochure ( PDF )

Features:

- Torque: 2.5 to 125 lb-in

(0.28 to 14.12 Nm) - Diameters: 1.25 to 3.27 in

(31.8 to 83.1 mm) - Efficient means of cycling load

- Fast response, repeatable

- performance

- Static or dynamic engagement

- Simple installation

- Economic cost

- Energy efficient

Typical Applications:

- Typical Applications

- Robotics

- Medical equipment

- Actuators

- Motor brakes

- Postal handling equipment

- Packaging