Air & Vacuum Pneumatic Actuators by Airpot®

Airpot Corp. has developed a family of unique pneumatic actuator products specifically designed to provide unparalleled force accuracy by eliminating friction from the working elements. The products satisfy actuation requirements ranging from undemanding levels of air cylinder force output for the most basic uses, to almost imperceptible levels of accuracy for the highest technology, most precise applications.

There are four categories of Airpot Pneumatic Actuators available: Self-Aligning Actuators, Airpel Anti-Stiction Cylinders, Airpel Plus Cylinders, and Airpel-AB Cylinders. All can provide a precise, accurate, repeatable motive or counterbalancing force or apply a gentle or precise holding, lifting, or squeezing force (as low as a few grams.) Applications include precise tensioning, positioning or supporting delicate materials, sensitive force control for holding or clamping fragile components, and counterbalancing and safety support for vertically positioned linear motor driven masses.

The materials and construction of all models provide built-in lubricity without actual lubricants, high strength-to-weight ratio, excellent stability under temperature/humidity extremes, close coefficients of thermal expansion, and non-deteriorating performance due to age or non-use. The basic parts are a piston (graphite or SS depending on model), precision ground to millionths of an inch TIR, closely matched to an annealed, borosilicate glass cylinder with a precision fire-polished bore.

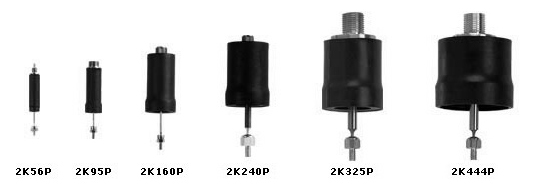

Self-Aligning Actuators

The Airpot® Self-Aligning Actuator is the most compact of the pneumatic Actuator line. It offers the most bore sizes, lowest mass, and uses low friction ball joints at both the piston and rod ends to allow the piston to self-align and reduce side loads. This product group makes possible accurate air cylinder force actuation and uniform motion with slow, smooth movement, even over distances less than 0.01 inch, or cycle rates at very high speeds up to 10 cps or more. There are a variety of rod connection choices available for easy, low friction mounting and alignment.

Self-Aligning Actuators

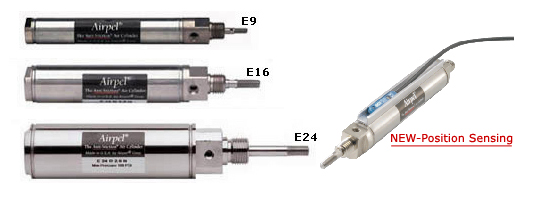

Airpel Anti-Stiction Cylinders

Airpel Anti-Stiction® Air Cylinders are built with an outer stainless steel sleeve and outwardly resemble common single acting and double acting air cylinders with standard mounting configurations. However, that’s where the similarity ends because the Airpel uses an inner glass cylinder and graphite piston which exhibit starting and running friction from less than 0.5% to 2% of load depending upon model, can operate at less than 2 psi, have no interference seals, use no lubrication, and can be used over an extreme temperature range with no change in performance. They are available in 3 Imperial and 4 metric bore sizes and strokes up to one meter.

Airpel Anti-Stiction Cylinders

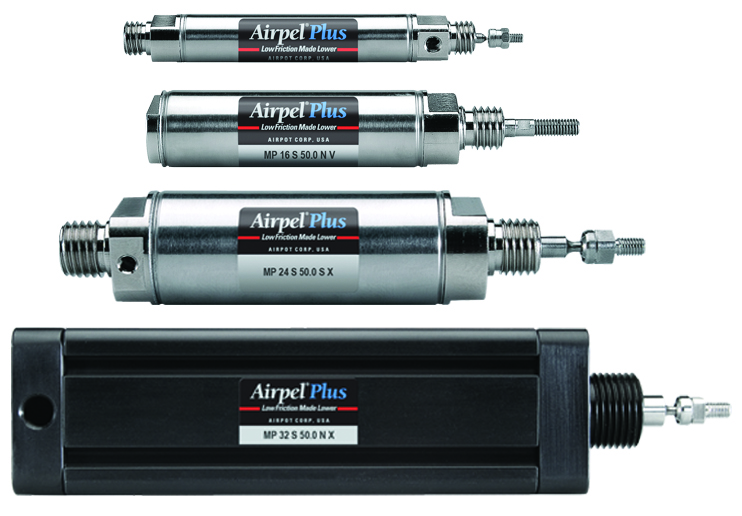

Airpel Plus Cylinders

Airpel Plus Cylinders -These Airpel models occupy the middle of the price / performance range between our standard Anti-Stiction® Airpel and the Force Without Friction® Airpel-AB®. The Airpel Plus uses the same graphite piston/borosilicate glass cylinder combination as our standard Airpel but the piston construction takes advantage of our Airpel-AB technology. The result is an air cylinder with friction levels only about 25% of the standard Airpel model. This allows for even greater force accuracy and more precise resolution while offering a significant cost savings over the Airpel-AB.

Airpel Plus Cylinders

Airpel-AB Cylinders

The Airpel-AB® Air Bearing Actuator offers the ultimate in accurate force control available from a pneumatic actuator. It is a truly unique device that combines air cylinder-like linear actuation with zero friction air bearing technology. It’s amazing "Force Without Friction®" feature is made possible by a precision ground stainless steel piston which is specially shaped such that the introduction of pressurized air into the Airpel cylinder creates a true air bearing airflow effect around the piston. With as little as 5 PSI of air applied to the cylinder, the same air that drives the piston also produces a stiff cushion of air to support the piston and prevents it from contacting the cylinder wall. This non-contact motion provides a force resolution to within 0.5 gram and gives the Airpel-AB virtually an unlimited life span. In fact, they are even guaranteed for the life of the original equipment in which they are used. The Airpel-AB air bearing pneumatic actuators are available in metric models with four bore diameters and ten standard strokes to provide precisely repeatable driving or supporting forces from 2 grams to 58 kg. Operating temperatures range from -20 C to +90 C.

Airpel-AB Cylinders

Product Comparison

Airpot Actuators:

- Self Aligning

- Most compact

- Single acting (extend with pressure, retractable by external spring or vacuum)

- Lowest mass

- Easiest to customize

- Outer rubber sleeve

- Operate with vacuum or pressure

- Friction less than 2% of load

- Operate with less than .2 psi

Airpel Anti-Stiction & Airpel Plus Air cylinders:

- Typical air cylinder mounting configurations

- Operate with vacuum or pressure in either direction (Single acting only for Airpel Plus)

- Can be pivoted

- Outer Steel sleeve

- Friction less than 2% of load (less than 0.5% for Airpel Plus models)

- Operate with less than .2 psi

Airpel–AB air bearing Actuators:

- Highest accuracy for the most challenging requirements

- Zero friction true air bearing airflow

- One way actuation (extension)

- Stainless steel non-contact piston

- Unlimited life