Allied Motion's Motor Solutions

Allied Motion designs and manufactures high quality motion control products specifically designed to meet the demands of a range of applications and industries. From durable brush DC motors for commercial equipment to sophisticated servo motors, drives and encoders for precision machinery, Allied Motion engineers always strive to achieve the best performing products at the best price to help our customers "change the game." Following is a list along with more details on Allied Motion's lines of products:

Brushless Torque Motors

Framless & Housed

Allied Motion offers the CM, HT and Megaflux series of high power density frameless and housed brushless torque motors.

These motors are computer‐designed and ‐optimized to provide the highest torque density available. Special attention has also been given to the minimization of cogging torque in these motors.

These frameless torque motors range in diameter from 19 mm up to 792 mm (0.8 in. ‐ 31.2 in.) and in stall torque up to 2020 Nm (1490 lb‐ft).

Direct integration of these motors onto the driven shaft eliminates the torsional resonance and backlash issues associated with traditional coupling and gearing mechanics.

The housed torque motors range in diameter from 66 mm up to 355 mm (2.6 in. ‐ 14 in.) and in stall torque up to 213 Nm (1885 lb‐in).

The newest models of Megaflux housed torque motors feature integrated encoders and electronic servo drives in addition to their own bearing system for a very compact, rugged unit that enables easier installation and commissioning than individual component solutions do.

- Brushless frameless and housed versions, computer-optimized for superior performance

- Diameters range from 17 to 792 mm (frameless)

- Peak torque ranges from 0.1 to 1024 Nm

- Housed versions include robust bearing system, encoder feedback, connectors in a rugged machined aluminum housing

- Matching servo drives available

Brushless DC Motors

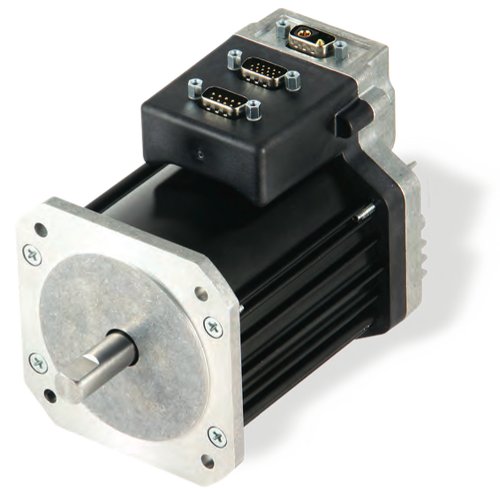

EnduraMax Series

Allied Motion’s EnduraMax brushless DC motors offer cost‐ effective torque, speed and/or position control for a broad range of A&D, commercial and industrial applications.

EnduraMax “s” models are engineered for speed control applications. The E75s and E95s series employ a patented sensorless brushless drive with the ability to start under load and attain over a 20:1 speed range.

EnduraMax “i” models are designed for closed‐loop torque, velocity or position control. They are equipped with an integral high‐count (4096 ppr) magnetic encoder, eliminating the need to add an external position sensor.

EnduraMax “n” models are available with Hall sensors only for use with separate external drives.

Choose from two EnduraMax frame sizes: 75 mm (2.95 in) with up to 375 W and 1.36 Nm (193 oz‐in) continuous output, or 95 mm (3.74 in) with up to 750 W and 2.4 Nm (340 oz‐in) continuous output. E95 models have a standard NEMA 34 interface.

With 12, 24 or 48 VDC windings, an EnduraMax brushless motor is the ideal solution in applications such as mobile HVAC systems, pumps, valves, linear actuators, mobile robots, conveyors and other material handling systems, to name just a few.

Brushless Servo Motors

Allied Motion offers high torque density brushless servo motors for precision velocity and positioning applications.

The Quantum (QB) series is offered in both frameless and standard NEMA housed versions. The frameless models are designed for direct integration with the driven shaft or gearbox. The housed NEMA models can be equipped with an encoder or resolver for feedback. Custom versions of the Quantum series to exactly match application requirements are easily developed from our standard platform designs.

- Standard NEMA 17, 23, and 34 frame sizes

- Computer-optimized to maximize performance

- Stall torque range from 11.5 up to 328 oz-in (0.08 up to 2.32 Nm)

- Continuous output power from 68 up to 846 Watts

- No-load speed up to 29,000 RPM

Permanent-Magnet DC Motors

Endurance Series

Allied Motion offers permanent-magnet DC motors in frame sizes and power levels to satisfy the needs of commercial and industrial applications with continuous shaft power requirements to one HP.

Available standard models are summarized below. Keep in mind that Allied Motion specializes in custom-design motion control products to fit specific application needs.

- Quality and durability in an economical brush DC motor designed for commercial and industrial application duty

- Continuous output power to 1 HP

- Standard frame sizes of 2.5, 3 and 4-inch diameter with smaller and larger sizes available

- Both maintenance-free and replaceable brush versions

- Custom mounting, shaft, connection, protection level easily accommodated to exactly match application requirements

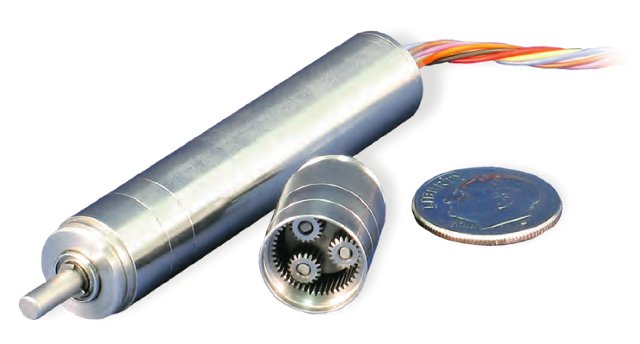

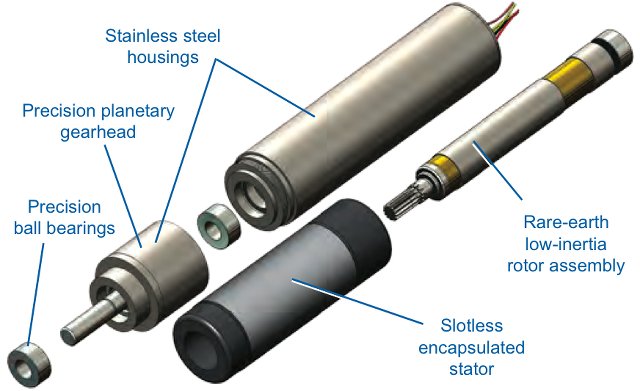

Brushless Slotless High Speed Precision Motors

PerformeX Series

Allied Motion’s PerformeX are rare-earth magnet, inner- rotor, slotless, small-frame brushless motors. The patented technology of the PerformeX motors enables them to deliver unprecedented torque and power levels of more than double that available with competitive motors of similar size.

PerformeX motors are specifically designed, including optional autoclavability, to power surgical handpieces, as well as for use in powered limb prosthetics and surgical robot systems.

PerformeX motors are capable of high speed operation to 100,000+ RPM. With our high performance planetary gearheads, speed may be traded for higher output torque delivered at high levels of efficiency.

The stainless steel gearhead body is equal in diameter to that of the motor to ease mechanical adaptation in restricted space applications. Standard ratios are 5:1 and 25:1, but non‐standard ratios are available as well.

Outer-Rotor Brushless DC Motors

KinetiMax Series

Our KinetiMax precision outer-rotor brushless DC motors are available with integrated drive electronics or as motor‐only models with Hall sensors.

The KinetiMax series employs an external rotor and iron core stator that minimize cogging and maximize output torque. These outer‐rotor designs are particularly well suited for medical, pump and scanner equipment applications.

Brushless Motor Drives

DPFlex, SXD & xDrive Series

Allied Motion offers modular brushless drives rated up to 4.4 kW continuous power to mate with our motors.

Our patented, innovative DPFlex sensorless brushless drives provide performance exceeding even conventional Hall‐commutated drives.

Our xDrive series are direct mains-fed digital AC servo drives able to drive up to 4.4 kW motors.

And, we also utilize our advanced drive technology in the form of compact drive assemblies for our integrated motor‐drive series.

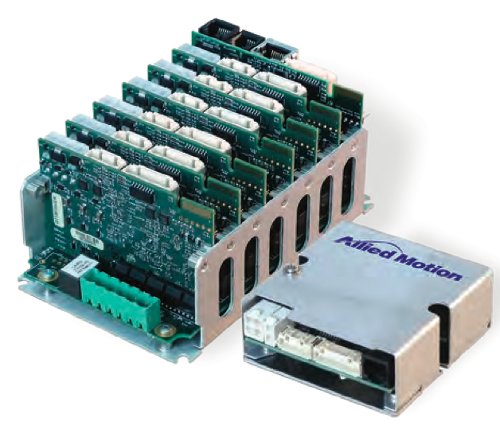

Modular Motion Controllers with Drive

MXC & SXC Series

Allied Motion’s MXC and SXC are high performance motion controllers with integrated brushless servo drives. The MXC multi‐ axis modular motion controller offers up to six axes (12 axes with a second rack housing) in a very compact mini rack housing.

The SXC is a single axis modular motion controller with servo drive, again in a very compact modular form factor.

These controllers provide full motion control capability, program storage, Ethernet bus communication, and high performance servo drive sections.

Optical Encoders

Incremental & Absolute

Allied Motion is an innovator in the design of Optical Encoders, especially for custom applications. Directly integrating custom encoders with motor actuators into custom designed frames is one of our strengths.

- Incremental and absolute models

- Resolution up to 2.25 million CPR (incremental), 14-bit gray (absolute)

- Modular (kit), shaft, hollow shaft, thru-bore models

- Large-bore models with ID bore up to 20+ in. (508+ mm)

- Digital, line-driver, and sine-cosine incremental versions

Gearmotors

Brushless & PMDC

Allied Motion offers BLDC and PMDC gearmotors in right-angle, parallel, and inline (planetary) shaft versions. Available standard models are summarized below. And keep in mind that Allied Motion specializes in custom-design motion control products to fit specific application needs.

- Right-angle, parallel, and inline (planetary) shaft versions

- Choice of BLDC or PMDC motor

- Continuous output power to 1/2 HP

- Cast aluminum gearboxes and precision gearing for durability and long life

- Custom versions available to suit specific application requirements

Precision Gearboxes

NEMA & Miniature High Speed

Allied Motion’s NP series precision NEMA planetary gearheads are designed as bolt‐on mates for Allied Motion motors.

NP units feature duplex bearings, optimized gear geometry, lifetime lubrication, and hardened gear and shaft components to extend service life, reduce noise/vibration and minimize maintenance.

Our MP series of miniature precision planetary gearheads are engineered specifically to combine with our PerformeX and similar‐sized motors to boost output torque while accommodating input speed up to 50,000 RPM. Precision MP gearheads minimize vibration and noise in surgical handpieces. Autoclavable (sterilizable) versions are available.

Transaxles

Brushless & Brush DC

Allied Motion offers three series of power differentiating transaxles, the DDA, TAA and the TAB series. The DDA series is a dual-drive unit that uses two opposed parallel-shaft gearmotors to effect the capability of a zero turn radius transaxle.

The TAA series is our standard-duty transaxle with up to 3/8 HP output shaft power, and the TAB series is our heavy-duty transaxle with over 1 HP output shaft power.

In addition to our standard transaxle offering shown here, Allied Motion can design custom transaxles to fit the requirements of your specific application.

- Standard and heavy-duty series of power differentiating transaxles

- 3/8 HP (standard) and over 1 HP (heavy-duty) shaft power capability

- Up to 2000 lb (907 kg) vehicle weight capacity

- Specifically designed for medical mobility and utility vehicle applications

Powered Wheels

WheelMaxTM Series

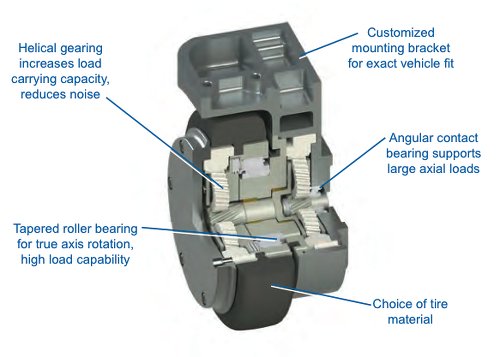

Our new WheelMax series are compact integrated traction wheel drives complete with wheel, tire, mounting bracket, and motor. A choice of a brushless motor with on‐board power drive electronics or a brush DC motor is available to complete the WheelMax.

WheelMax is specifically designed to provide traction in autonomous electric mobile vehicles in a broad range of applications. Electrically powered wheels are increasingly used in automated as well as manually‐guided vehicles for the transport of material and persons in a variety of settings from factories to hospitals to the field.

Allied Motion’s WheelMax series offers two‐stage epicyclic helical gearing for increased life and load capacity and reduced noise. The gear geometry of the WheelMax is optimized to maximize life and minimize noise and vibration.

Lifetime lubrication minimizes maintenance, and the wheel and tire are designed for quick exchange of the wheel and/or tire. IP54 is the standard environmental protection level.

A customized mounting bracket can be supplied to meet exact vehicle mating requirements.

An optional add‐on electric steering module is available to complement the WheelMax and provide a complete steerable electric wheel drive.

WheelMax with optional electric steering module